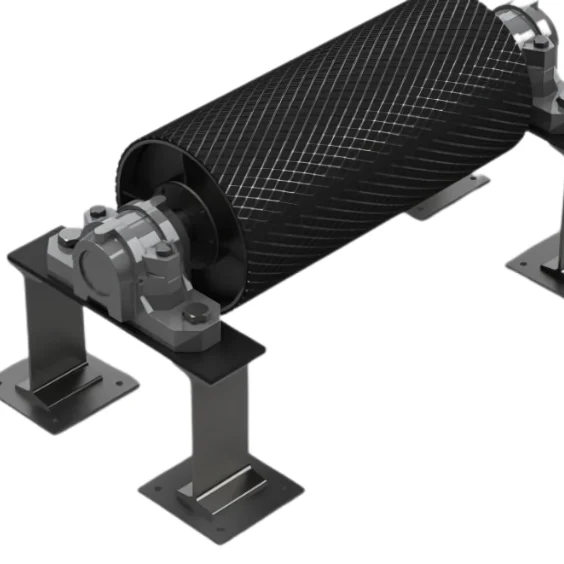

Pulleys

Pulleys are vital components of conveyor systems, used to drive, redirect, and maintain the tension of the conveyor belt. Constructed from high-strength steel or stainless steel, pulleys are engineered to support heavy loads and maintain operational stability across a range of industrial applications. Proper selection of pulley type ensures increased efficiency, minimized wear, and consistent performance.

- EHead Pulleys

- ESnub Pulleys

- ETake-Up Pulleys

- EBend Pulleys

- ETail Pulleys

- EDeflector Pulleys

Head Pulleys

The Head Pulley is located at the discharge end of the conveyor and is usually connected to the drive motor. It pulls the belt and drives the conveyor system forward. Head pulleys are commonly rubber-lagged to enhance grip and reduce slippage.

Snub Pulleys

The Snub Pulley is placed close to the drive pulley to increase the wrap angle around the drive pulley. This helps improve traction and minimizes belt slippage without transmitting any driving power itself.

Take-Up Pulleys

The Take-Up Pulley is part of a tensioning system. It maintains the proper tension of the conveyor belt by compensating for belt stretch and wear. These pulleys are mounted on adjustable frames or gravity-based setups.

Bend Pulleys

Bend Pulleys are used to redirect the belt in a different direction and are located at various transition points. Although they don’t drive the belt, they are critical for guiding and stabilizing belt movement.

Tail Pulleys

The Tail Pulley is located at the loading or tail end of the conveyor. It guides the belt onto the return side and helps keep it aligned. Tail pulleys may also include cleaning mechanisms for removing debris from the belt.

Deflector Pulleys

Deflector Pulleys are used to guide the belt away from obstacles or to assist in material discharge. These pulleys are strategically placed to alter the path of the belt slightly without changing its overall direction significantly.